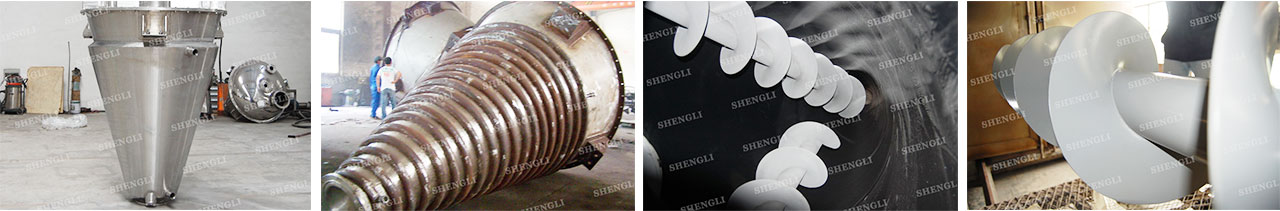

1.material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; different material can also be used in parts, between the part contact with the raw material and the parts don’t contact with the raw material. Surface treatment for stainless steel can be sandblasting, wiredrawing, polishing, mirror polishing.

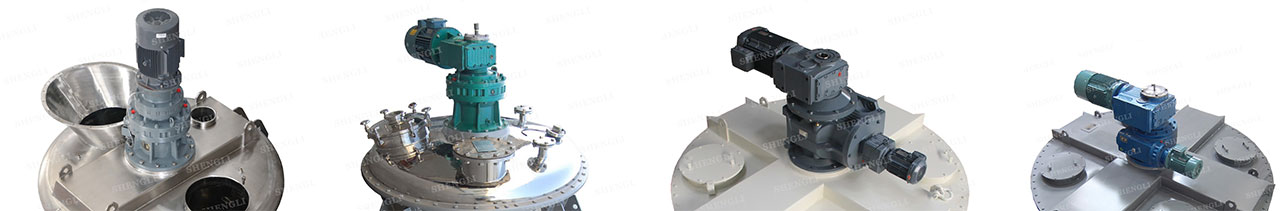

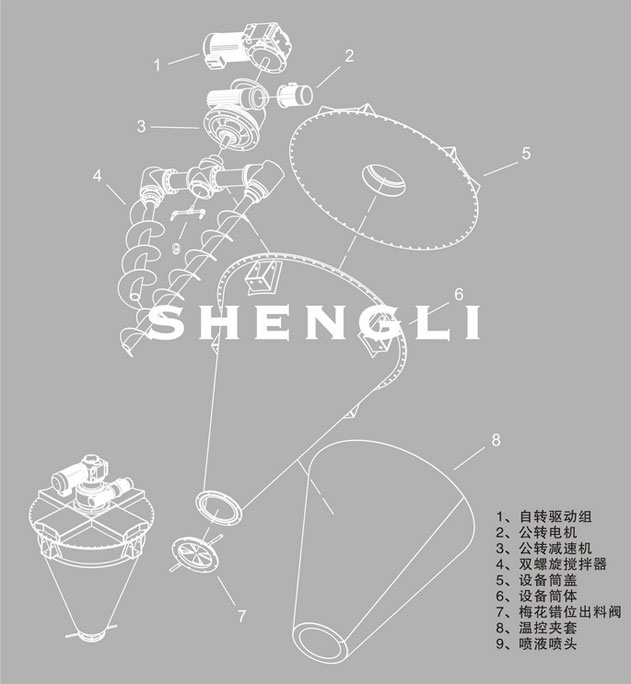

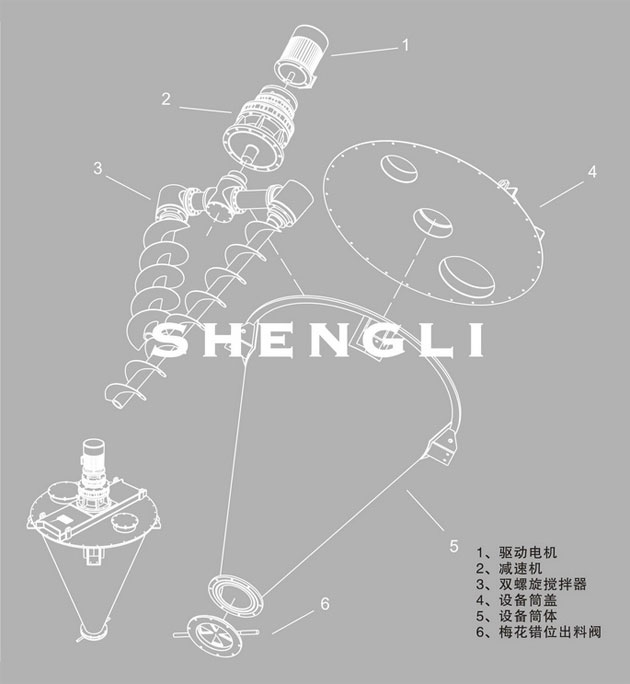

2.driven unit

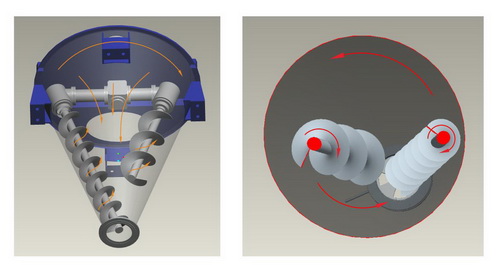

The driven unit and power is varied according to different raw material, starting method, and processing.

Double screw conical mixer is equipped with appropriative double output reducer, which combines pinwheel, gear and warm and gear.

3.discharging unit

Spherical valve or plum-blossom dislocation valve is matched to the double screw conical mixer.The surface of the valve match the track of the bottom of screw, to reduce the mixing dead zone to the maximum, and to make the largest discharging area, so as to make sure no leftover. Spherical valve has excellent sealing effect to powder, liquid and even in the negative pressure state.Plum-blossom dislocation valve is easy to operate and control the discharging speed

4.auxiliary components

Equipped with circulation medium of jacket, the double screw conical mixer can realize the temperature control in mixing process.

In the mixer barrel, the part contact with material can coat some antiriot, anti-caking and metal isolation material according to different ingredient. In some severe wear conditions, the screw surface can be overlaid by some wear proof alloy.

If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles.

|

Configuration 1: conical mixer with manually feeding |

|